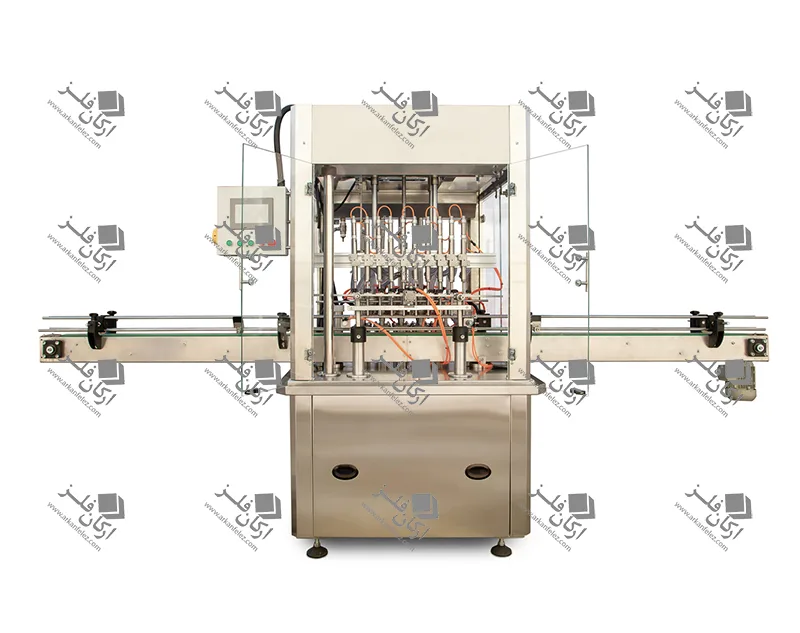

Suitable for filling all kinds of thin and thick materials from 100 to 1000 grams

General Product Specifications

- Filling all kinds of thin and thick materials from 100 to 1000 grams in one stroke and 1000 grams to 2000 grams in two strokes

- Product filling speed is about 45 1 liter bottles per minute. (Depending on the type of product).

- The accuracy of the device is within 1 percent.

- All parts in contact with the material are made of 316L stainless steel with a thickness of 1.15 to 3 mils and the device cover is made of 304 stainless steel.

- It has a conveyor belt with a length of 4.5 meters made of wear-resistant polyamide.

- Equipped with ESTOUN brand servo motor and Taiwanese ball screw for the main motor.

- It has a PLC of FATEK Taiwan and a touch panel of INVET Korea.

- Equipped with 10 pneumatic steel valves.

- The material volume can be adjusted through software.

- All nozzles and cylinders are machined by precision instruments (CNC).

- The chassis of the machine is of heavy profile type with epoxy paint coating.

- The machine has a height adjustment system for different containers.

- All electrical panel accessories are of Schneider Germany.

- Sensors are of AUTONICS Korea.

- Pneumatic accessories are of the original AIR TAC brand from Taiwan.

- The machine is equipped with a material drip catcher under the nozzles and an automatic CIP system.

- The machine’s cover plate has a gutter for easy washing.

- The machine has software definition for 5 different types of bottles.

- The machine is equipped with a 240 liter tank and a drain valve and 10 steel material inlet valves, an electronic follower and a water gauge.