+40

experience

About us

orem Ipsum, sometimes

referred to as ‘lipsum’, is the placeholder text used in design when creating content. It helps designers plan out where the content will sit, without needing to wait for the content to be written and approved. It originally comes from a Latin text, but to today’s reader, it’s seen as gibberish

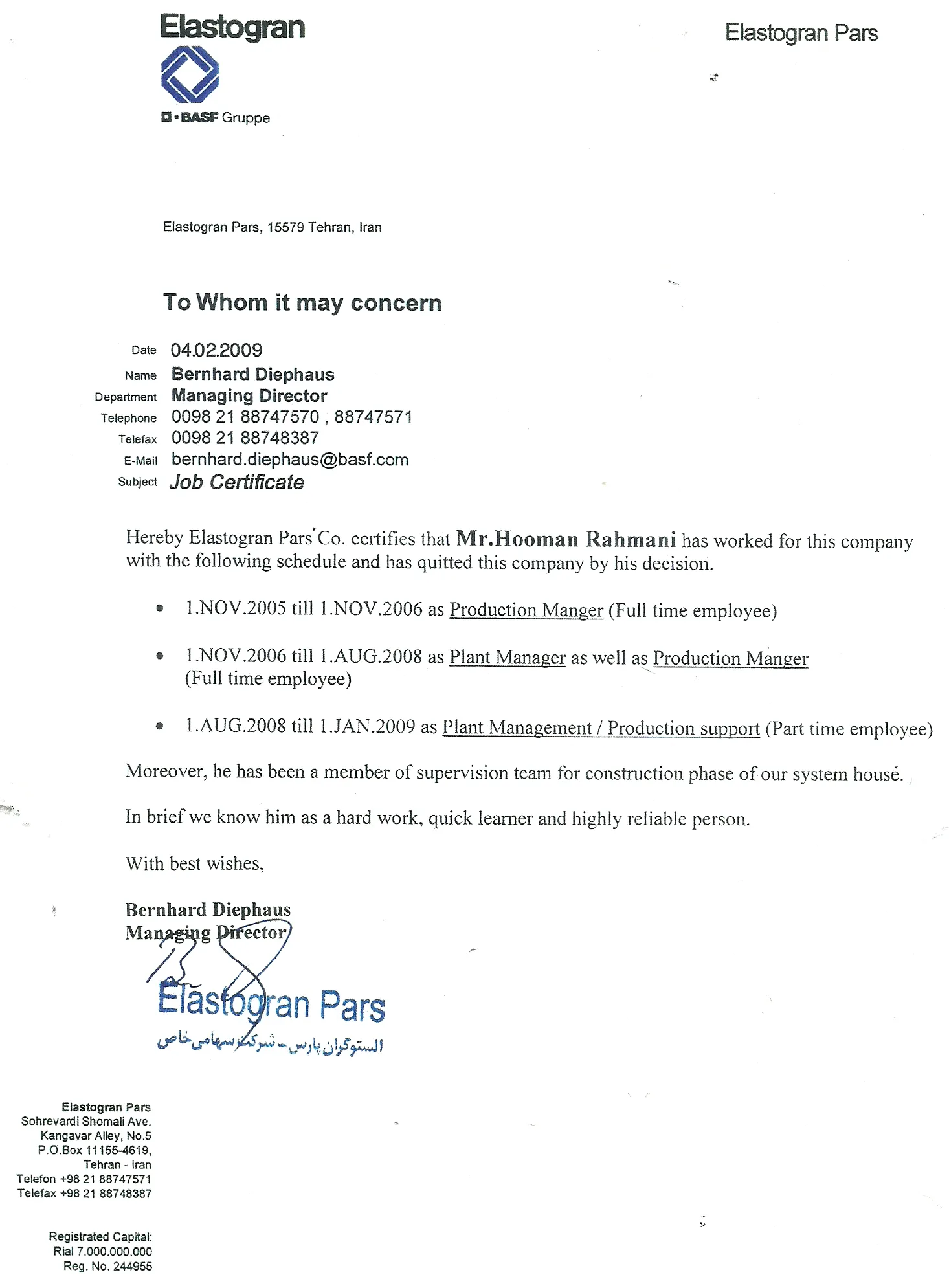

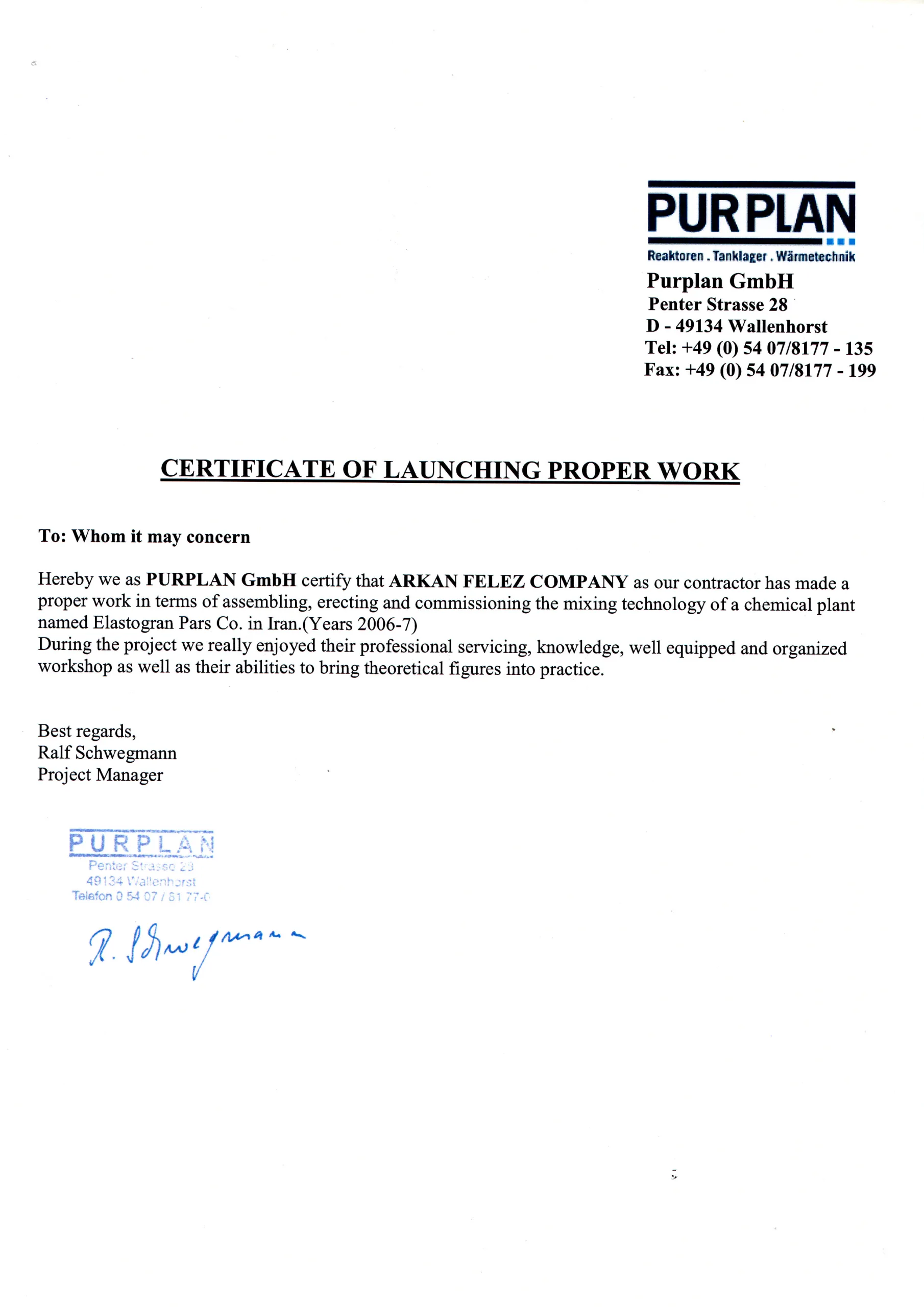

About ARKANFELEZ

- Year of establishment: 1984

- A knowledge-based company recognized by the Vice President for Science and Technology of IRAN since 2016

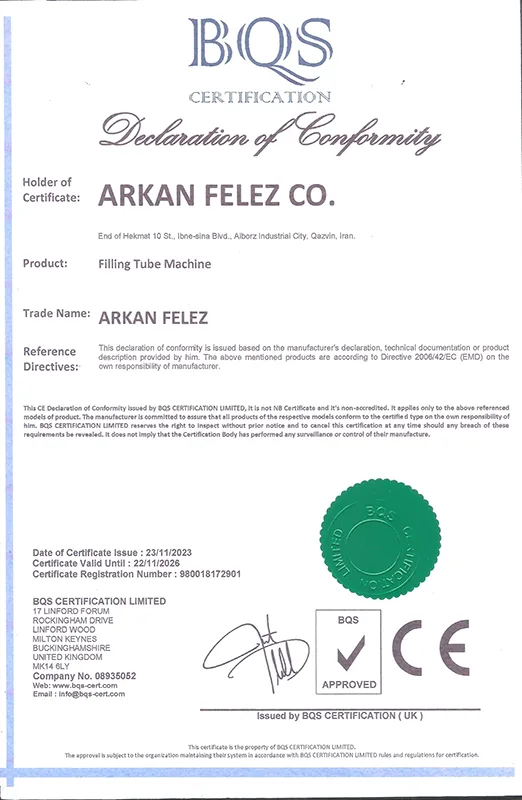

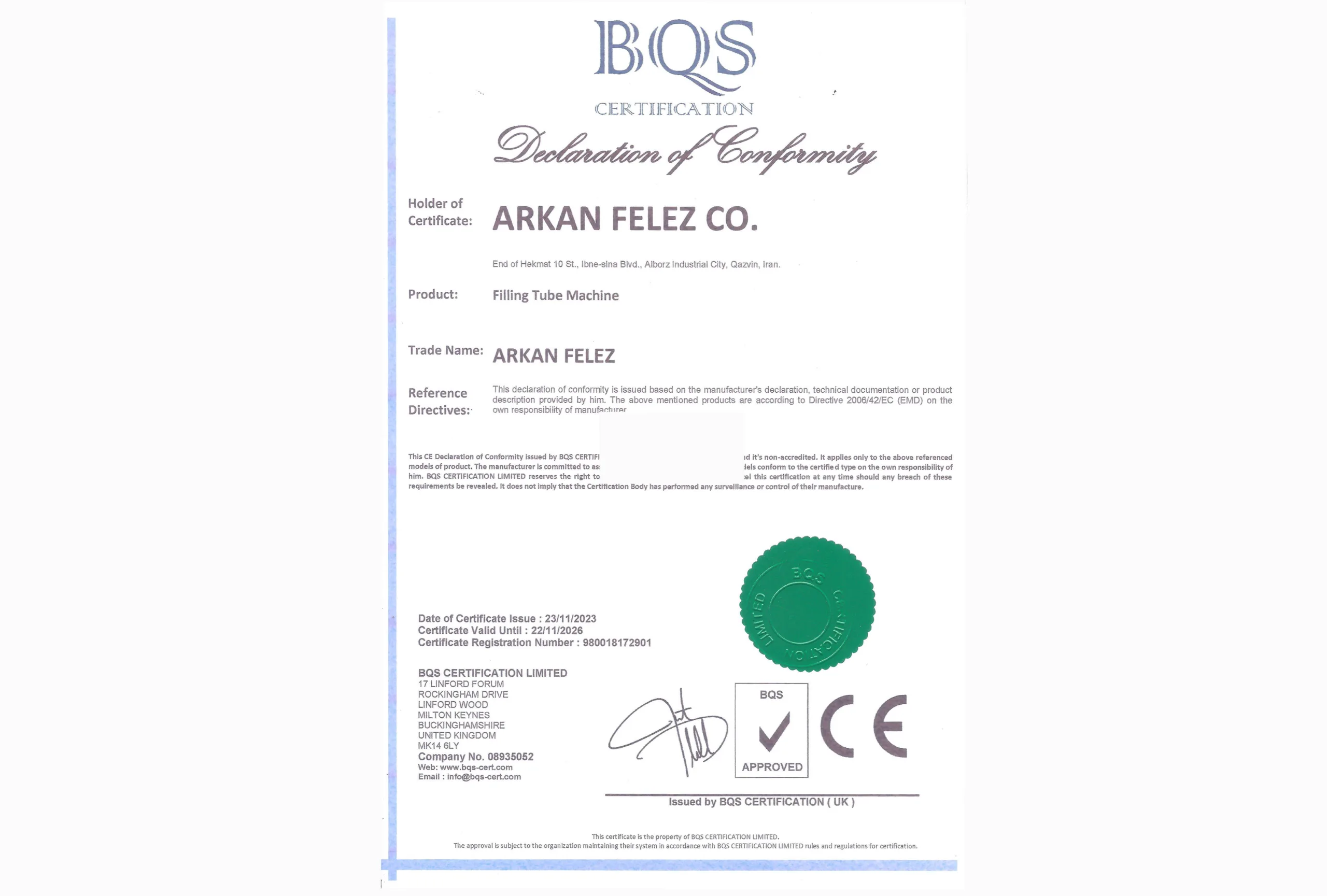

- Has the European CE standard mark

- Member of the Iranian Food Industry Machine Makers Association

- The first and largest manufacturer of vacuum homogenizer mixers in Iran

- The first and largest manufacturer of Inline homogenizer pumps in Iran

- The first and largest manufacturer of multistage pumps in Iran

- The first manufacturer of fully automatic metal door closers in Iran

- Production of more than 428 vacuum homogenizer mixers in different dimensions and technical specifications (until the end of autumn 2024)

PRODUCTS

Vacuum Homogenizer Mixer – VC Model

Vacuum homogenizer mixer for producing all kinds of emulsions and suspensions used in cosmetic industries

Vacuum Homogenizer Mixer – VX Model

Vacuum homogenizer mixer to produce all kinds of emulsions and suspensions used in cosmetics

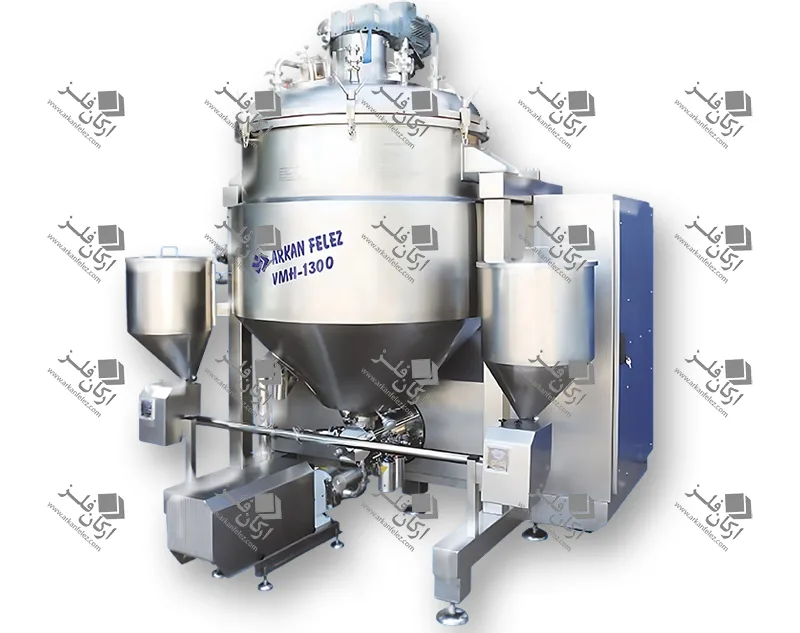

Vacuum Homogenizer Mixer – VMH Model

Vacuum homogenizer mixer for producing all kinds of emulsions and suspensions used in food, cosmetic, pharmaceutical and chemical industries.

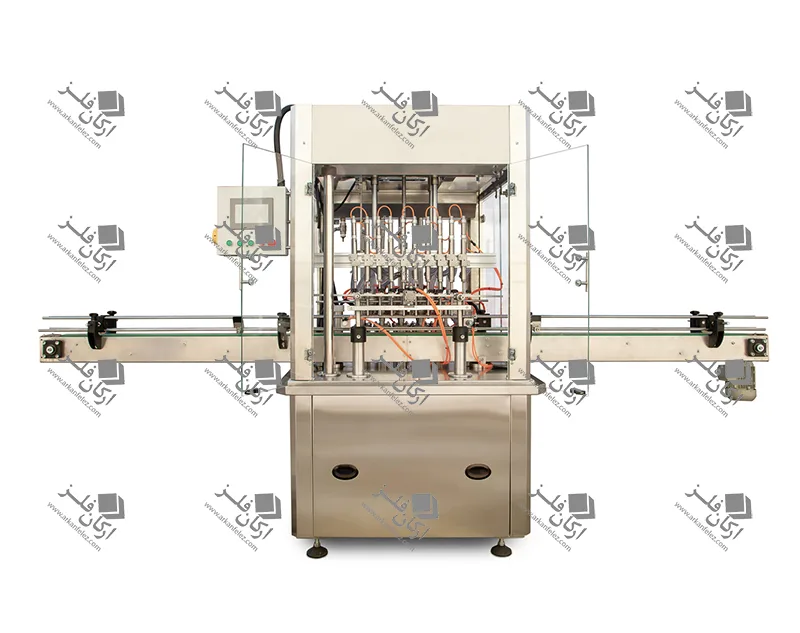

10-Nozzle Linear Filling Machine

The servo linear filling machine has 10 nozzles and is suitable for all types of thin and thick materials from 100 to 1000 grams.

Fully Automatic Laminate and Aluminum Tube Filler

The super filling machine is a 12-hole tube that is capable of filling thick and semi-thick substances such as shampoo, hand and face cream, all kinds of gels, etc. fill in multi-layered and laminated polyethylene tubes.

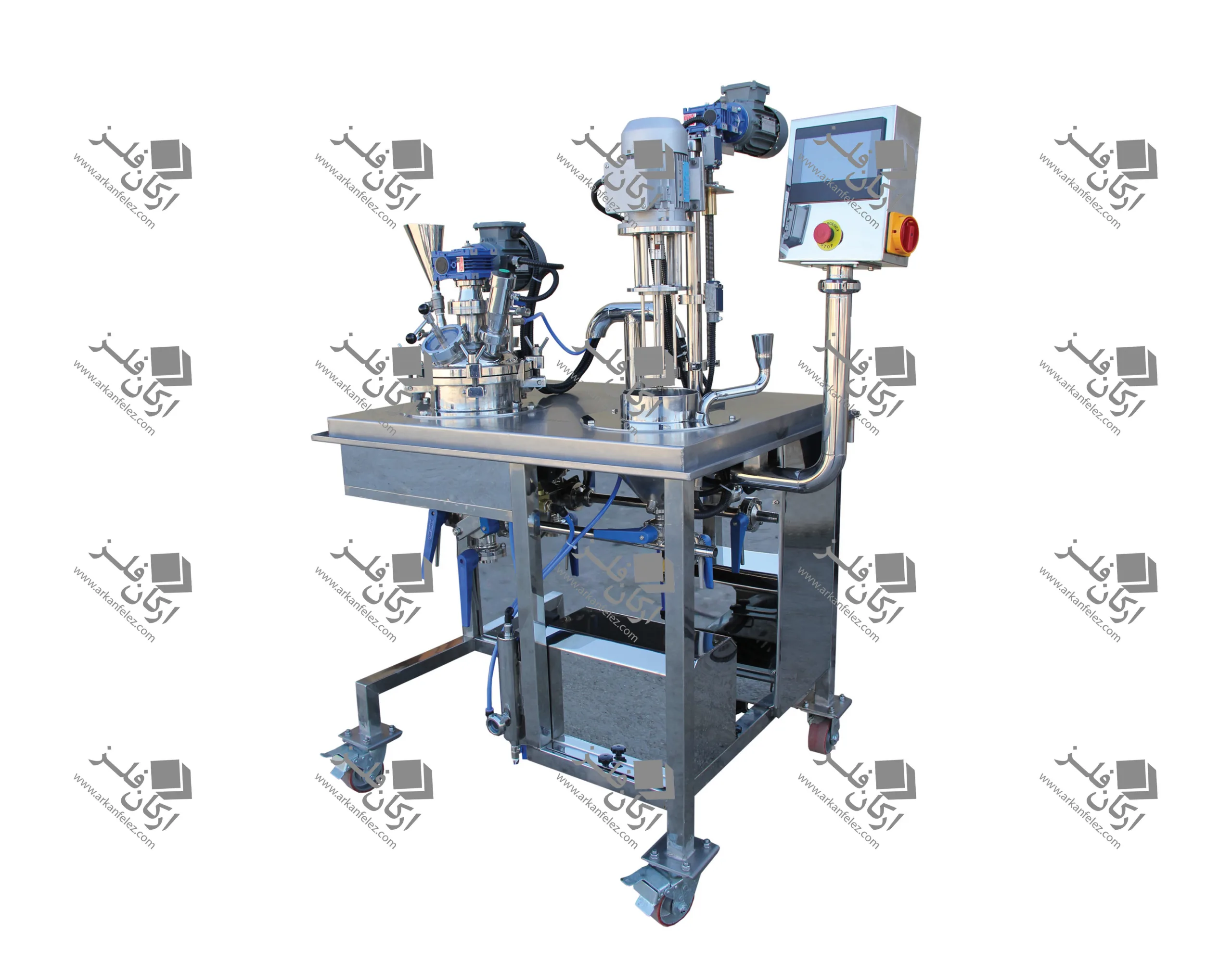

Vacuum Homogenizer Mixer – VMH Lab Model

Vacuum homogenizer mixer for producing all kinds of emulsions and suspensions used in food, cosmetic, pharmaceutical and chemical industries in small and laboratory volume.

Customers and Honors

foad ara

kaleh

test

nami noo

danoosh

mahram

roshd

namika

pichak

koochin

parjak

achachi

baghaa

limoo

yeko yek

tabarok

delvaseh

sun star

oghab

kamkar

orvabon

chika

sahar

chin chin

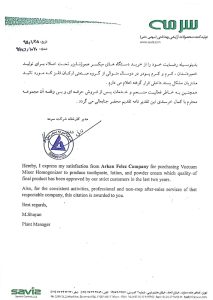

saviz

sehat

maz maz

zoshk

atousa

test

paviz

koochin

rana

bidestan

paknam

vitana

tak

danet

shirin asal

firooz

Lorem Ipsum, sometimes referred to as ‘lipsum

Address

Address:

End of Hekmat 10th

Alborz Industrial City

Qazvin, IRAN

Work Hour

Work Hour:

07:30 – 16:30 (UTC +3:30)

Saturday – Wednesday

Phone:

Last News and Articles

Introduction Industrial mixers are devices used to mix different materials in various industries. These mixers are divided into different types depending on the need and type of materials. Below, we have examined some of the most important types of industrial mixers: Vertical Mixers: These types of mixers are used to mix powdered and granular materials. The movement of materials in a vertical direction ensures uniform mixing. These devices are especially used in the animal feed and chemical industries. Horizontal Mixers: Horizontal mixers are used to mix large volumes of materials. These types of mixers are usually used in the feed, pharmaceutical and food industries. Powder Mixers: These mixers are designed to combine powdered and granular materials. They are usually used in the food, pharmaceutical and chemical industries and can mix different types of powders uniformly. Homogenizer Mixers: These devices are used to mix materials with precise and uniform composition. They are especially used in the pharmaceutical and chemical industries to produce high-quality materials. Industrial mixers play a key role in various industries, especially in the production of food, medicine, chemicals and even in the construction industry. Homogenizer Mixer A homogenizer mixer is one of the important devices in various industries that is used to mix materials in such a way that a uniform and homogeneous composition is obtained. This device is especially used in the food, pharmaceutical, chemical and cosmetic industries and is used for processes such as emulsification, mixing and reducing the particle size of materials. The operation of the homogenizer mixer is based on the compression and spraying of materials under high pressure. In this process, the materials pass through a nozzle at high speed and pressure and become very fine and uniform particles. This improves the quality of the final product and increases its shelf life. The homogenizer mixer is used in the production of products such as sauces, medicinal creams, sweets, medicinal powders, paints and cosmetics. This device also helps to improve the texture and uniformity of products and plays an important role in preventing the separation of materials in liquid mixtures. By using the homogenizer mixer, the production process can be optimized, production time can be reduced and the quality of products can be improved. This device is one of the essential tools for producing high-quality products with a long shelf life. Shampoo Homogenizer Mixer Shampoo homogenizer mixer is used to produce shampoos with a uniform and high-quality composition. This device uses high pressure and a homogenization process to convert the various ingredients in the shampoo formulation into fine and uniform particles and helps prevent the separation of materials. The operation of the shampoo homogenizer mixer is such that the combination of shampoo raw materials such as water, surfactants, oils, fragrances and dyes passes through a series of nozzles under high pressure. This process causes the particles in the shampoo to mix evenly and a smooth and uniform final product is obtained. The homogenizer mixer is very important in the production of shampoos that require stable emulsions. This device helps prevent the separation of various ingredients and create the appropriate foam and concentration. Also, using this device increases the quality, improves the texture, increases the shelf life and optimizes the shampoo production process. Ultimately, the shampoo homogenizer mixer is an essential tool in the health product manufacturing industry that helps produce high-quality and better-performing shampoos. Laboratory Homogenizer Mixer A laboratory homogenizer mixer is a device used to create uniform mixtures and reduce particle size on a small scale. These devices are especially useful in laboratories, scientific research, and manufacturing industries that require testing and producing small quantities of products. The function of a laboratory homogenizer mixer is similar to industrial devices, except that its design and capacity are optimized for use on a laboratory scale. The materials pass through special nozzles under high pressure, and this process converts large particles into fine and uniform particles. These devices are used in various fields such as the pharmaceutical, food, cosmetic, and chemical industries. For example, in the production of creams, lotions, suspensions or emulsions, a laboratory homogenizer mixer helps to create a uniform and high-quality mixture. A laboratory homogenizer mixer allows scientists and researchers to test different formulations and evaluate the final quality of products before large-scale production. This device is also very effective in increasing the accuracy and speed of experiments and reducing waste. Laboratory Mixer A laboratory mixer is a device used to mix and blend materials on a small scale. These devices are used in laboratories and scientific research and help produce uniform and homogeneous mixtures. Laboratory mixers can mix liquid, powder and granular materials. These devices are used in various industries including pharmaceutical, food, chemical and cosmetic. Laboratory mixers are usually designed in different sizes and with adjustable mixing speed and time to meet different experimental needs. What is a homogenizer? A homogenizer is a specialized tool designed to produce uniform mixtures of liquids and semi-solid materials in various industries. This device uses high pressure to pass the materials through one or more nozzles, which reduces the particle size and creates a homogeneous mixture. Homogenizers are used in the food, pharmaceutical, cosmetic and chemical industries to produce products such as sauces, creams, ointments and beverages. These devices help improve the quality of products and prevent the separation of materials and the formation of layers in liquids. Also, by reducing the size of particles, the absorption and effectiveness of materials in the final products are improved. Homogenizers help increase the shelf life and stability of products and at the same time speed up the production process. As a result, the homogenizer is one of the important tools for producing high-quality and uniform products, which is especially important in industries sensitive to uniform mixing and quality control. Vacuum Homogenizer Mixer Device The vacuum homogenizer mixer device is an advanced tool designed to mix materials uniformly and under vacuum conditions. This device uses negative pressure inside the mixer chamber to bring particles and molecules together, […]

Shampoos are a combination of surfactants, softeners and many other materials in a water solution. In addition to shampoos that are used only for hair washing, there are also shampoos that are used for two purposes. Also products that have properties such as dandruff treatment; Shampoos are used to protect the effect of ultraviolet or for hair washing hair (although ordinary shampoos are also used to wash colored hair) or have medicinal properties. Shampoo production process A conventional production process is as follows: The water temperature inside the process tank is measured. This water is heated to 50-60 ° C to help dilute and dispersion other materials. The first material added to the solution is surfactant because other additives, especially those that affect viscosity, can make it more difficult to dilute surfactant. The softener and other materials are added. The PH of the solution is adjusted to the required amount. Sodium chloride or other viscosity modifiers are finally added with color and aroma. Challenges of the production process When using regular mixers you have a number of problems: Aeration (air mixing with the product) should be avoided, as this will cause transparent shampoos and instead of the product, it takes part of the product packaging. Silicones are impermeable with water and are chemically incompatible with some surfactants. As a result, it makes the emulsion or suspension very difficult. Ordinary mixers cannot create enough shear amounts for silicones to get them as needed, so emulsion or sustained suspension is not achieved. These mixers further increase aeration and bubble. Many viscosity ingredients are much higher than water. When mixing with mixer, higher viscosity materials form bullets that are spread to the solution without dilution and dispersion. Concentrated materials such as carbomers and cellulose -based products may require high shear mixing to activate. As viscosity increases, the addition of sodium chloride becomes increasingly difficult. To overcome these problems, shear mixer (homogenizer) is needed at high speed, as it is used by conventional mixers of air bubbles in the product. Solution provided by ArkanFelez Company These problems can be resolved by the use of a homogenizer mixer of the ArkanFelez Company. A vacuum homogenizer mixer can quickly mix liquids with different viscosity. Under the vacuum, the mixer forms a closed system and prevents air from penetrating into the tank and the formation of the bubble. A dramatic decrease in the mix time results. It significantly increases the performance of thickening materials compared to traditional methods. Enhances the quality and recurrence of the product. Due to the vacuum of the mixer, it is possible to perform the dearabation process.

Medications for the treatment of conditions such as skin diseases, skin irritation, bite, fungal infections, etc. are typically produced as cream or ointment because it is an effective way to deliver the drug directly to the body. The raw materials needed can be as water emulsions in oil or oil in water, consisting of waxes, softeners and lubricants in an oil phase or in a water phase containing emulsifying, stabilizing, thickening materials, materials Prepare and in some cases color. The active ingredients are scattered at each stage or are added when the emulsion is formed. Production process The ingredients, formulations and viscosity of the products are widely different, however, a conventional production process is divided into four separate operations: Preparation of oil phase: Powder ingredients, which sometimes dry before the process begins, are scattered in mineral oil or silicone oil. Heating may be needed to melt some materials. Scattering of water phase ingredients: Concentrates and stabilizers are dissolved in a separate container in water. Heating may be necessary to accelerate the process. Emulsion formation: Two phases are mixed with high speed hemorrhoids to form emulsion. Distribution of active substance: The active ingredient often forms only a small portion of the formulation. To maximize the efficiency and effectiveness of the product, it must be properly scattered. Production challenges Using regular mixers you will have a number of problems: By adding water, thickening, stabilizing and emulsifying materials can form pellets that mixers cannot break down. Similarly, the oil phase ingredients can form masses that require stress for dispersion. The ingredients to obtain the viscosity needed and the development of performance must be completely hydrated. The materials that are not completely dissolved are attached to the tank wall and parts of the mixer. Mixers cannot reduce the particle size enough to stabilize the emulsion. Active material can be temperature -sensitive. The cooling of the product before adding active ingredients increases the process time. Poor dispersal of active ingredients disrupts the effectiveness of the product. To obtain a uniform and sustainable end product, additional time and equipment are required. Solution provided by ArkanFelez Company The ArkanFelez vacuum homogenizer mixer can quickly dissolve solids in liquids, break down thickening, stabilizing and bullets, and completely reduce the size of the particles to make emulsion and suspension stable. The mixing time decreases dramatically, while the uniformity and consistency of the product improve greatly. Sustainable emulsion Mix without bubbles Reduces the mixture of the mix dramatically. The performance of the raw materials as thickening materials maximizes and other materials are completely scattered. The initial mixing stage of the powder material can be removed. The water phase can be produced at ambient temperature and reduced heating costs. It also accelerates the cooling of the mix and reduces time and cost of the process. The quality and repeat of the product

Lorem Ipsum, sometimes referred to as ‘lipsum’, is the placeholder text used in design when

creating content. It helps designers plan out where the content will sit