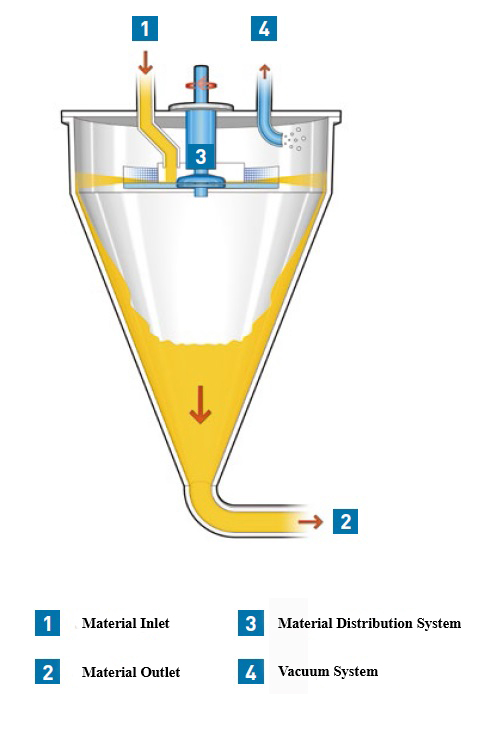

A vacuum bubbler is a vacuum system for bubble-freezing liquid, semi-liquid or paste products

Applications

Food industries: Various hot and cold sauces, ketchup, mayonnaise, pastry cream, cake gel, baby food, flavorings, nutritional supplements, vitamins, juice

Cosmetic industries: Cosmetic powders, cosmetic pancakes, lipstick, mascara, hair glue, masks, hair dye, varnish, creams, color pigments, lotions, toothpaste, shampoo

Pharmaceutical industries: Medical creams, gels and ointments, eye medicines and skin products

Chemical industries: Adhesives, inks and greases, varnishes, microsilica gels in the construction industry, hard hydrocarbon homogenates, fertilizers, shoe polish, car wax, plant pesticides and agricultural pesticides

In the process of producing semi-thick liquids and high-viscosity products, air bubbles (or other gases) are unintentionally formed in the product. This not only causes undesirable effects such as oxidation (spoiling of oil and fat inside the product), changes in aroma, taste, color and shortening of the product’s expiration date, but also creates numerous problems in weight packaging (especially tube packaging) due to the decrease in product density.

The vacuum bubble trap designed by Chroma Germany is an ideal solution for eliminating bubbles trapped in high-viscosity products.

This device, like a very precise filter, separates all bubbles from the product and improves the quality and texture of semi-solid products (various creams, sauces, hair dyes, ointments, lotions, toothpaste, etc.).

According to Chroma Germany’s recommendation, the most suitable place to install this device is immediately after the mixer or just before the filling machine.

Equipped with a pneumatic door, sight glass, independent vacuum pump with automatic vacuum control mechanism and speed adjustment by inverter.