Fast particle size reduction and rapid suspension

Applications

Food industries: All kinds of hot and cold sauces, ketchup, mayonnaise, pastry cream, cake gel, baby food, flavorings, food supplements, vitamins, juice

Cosmetic industries: Cosmetic powders, cosmetic pancakes, lipstick, mascara, hair glue, mask, hair dye, varnish, creams, color pigments, lotions, toothpaste, shampoo

Pharmaceutical industries: Medical creams, gels and ointments, eye medicines and skin products

Chemical industries: Adhesives, inks and greases, varnish, microsilica gels in the construction industry, hard hydrocarbon homogenate, fertilizers, shoe polish, car wax, plant pesticides and agricultural pesticides

General product specifications

- Ideal for rapid particle size reduction and rapid suspension

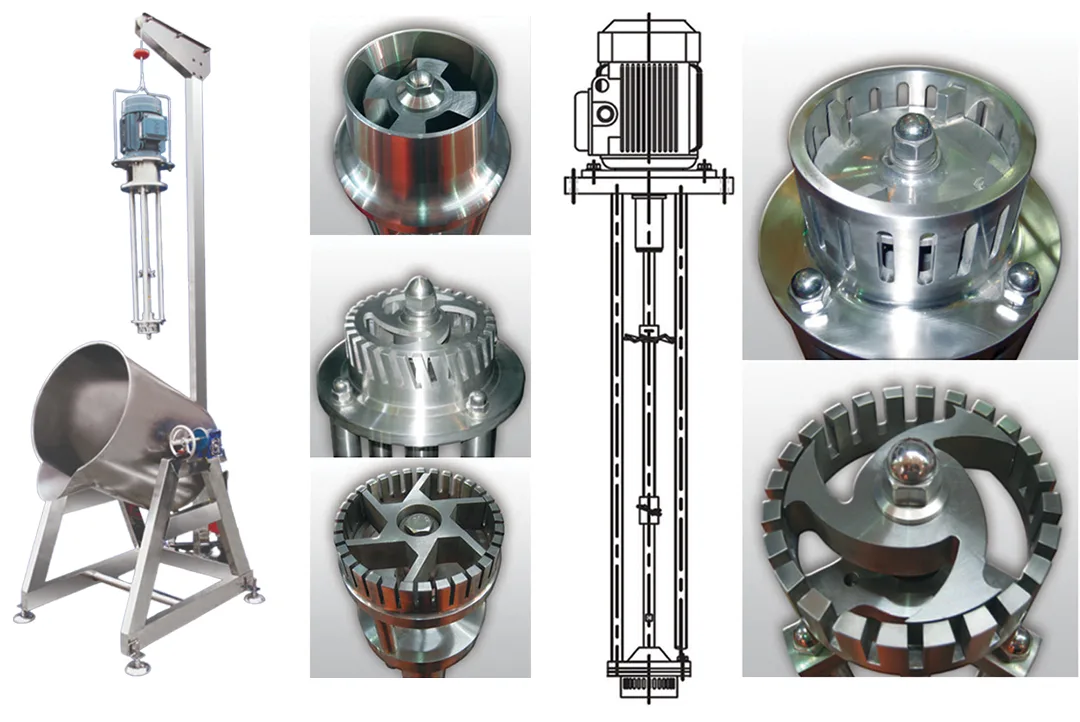

- Permanent installation or hanging on the mixing tank

- If installed as a hanging: Possibility of raising and lowering the mixer during operation – possibility of using a Mixer for multiple tanks (manual, pneumatic, hydraulic and hydropneumatic elevators can be ordered)

- The flow rate from the rotor is several times the flow rate from a similar Inline Homogenizer.

- Suitable for dispersion, homogenization and emulsion

- The ability to add blades to the rotating shaft to intensify the mixing power or create a whirlpool

- Easy to wash and disinfect

- Very simple structure and the ability to install several different heads on a mixer

- The ability to install an inverter to increase (or decrease) the mixing intensity or the shear stress applied to the fluid

- The ability to use spark-proof motors (Ex-Proof) to work with flammable fluids (such as alcohol)

- Consult our experienced staff to select the appropriate head type