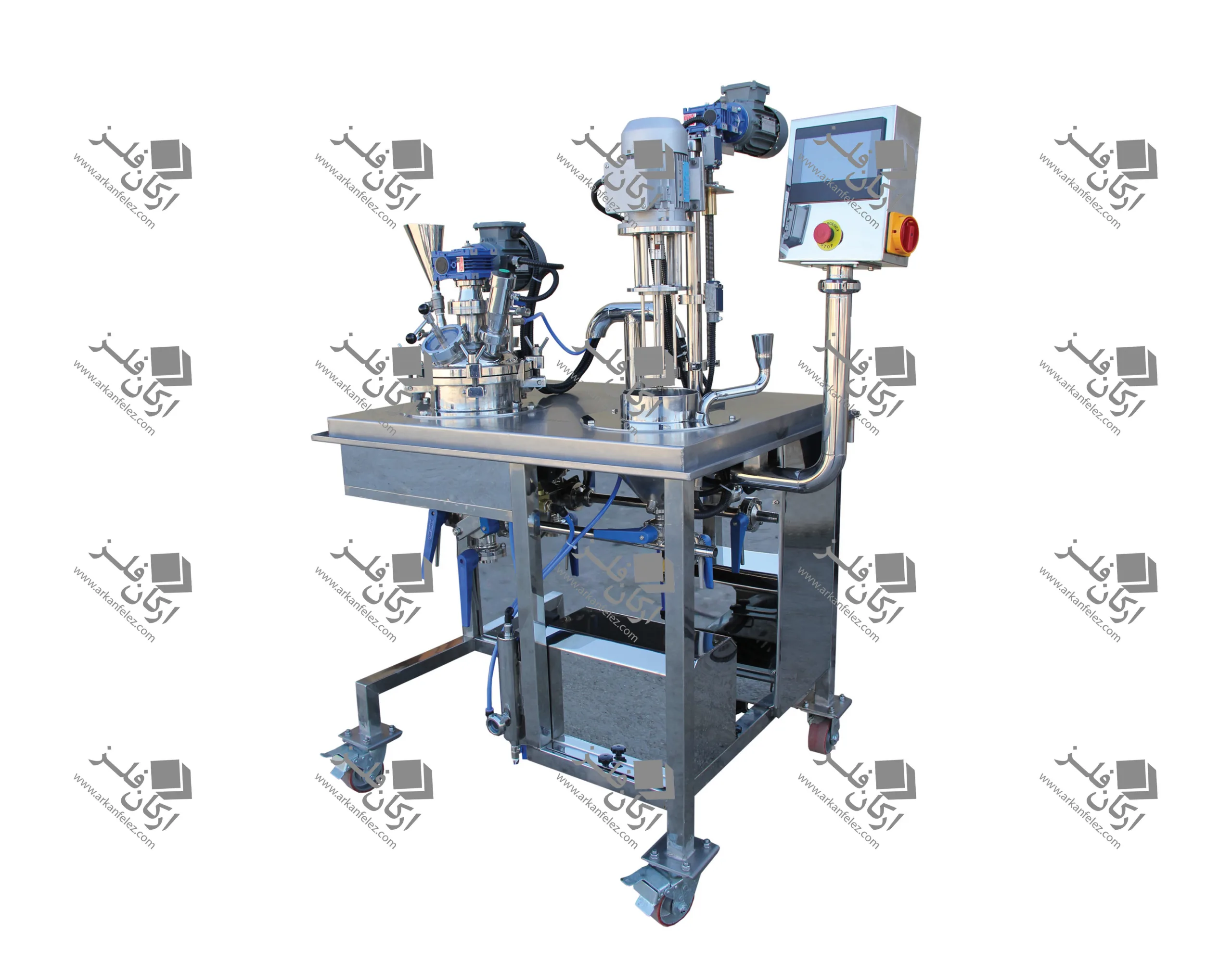

General specifications and application of laboratory vacuum homogenizer mixer

The laboratory vacuum homogenizer mixer is made based on a European design (German Chroma design) and all its parts are made of durable stainless steel. This device has a double-walled mixer with a capacity of about 8 liters, which can produce batches weighing about 2 to 8 kg.

Main applications:

🔹In the food industry: production of various hot and cold sauces, mayonnaise, pastry cream, cake gel, juice, flavorings, supplements and vitamins

🔹In the cosmetic and health industries: production of foundation, pancakes, lipstick, mascara, varnish, hair dye, shampoo, toothpaste, hair glue and mask

🔹In the pharmaceutical industry: preparation of gels, creams, ointments, syrups and supplements

🔹In the chemical industry: production of adhesives, grease, ink, microsilica, fertilizers, wax, pesticides and building compounds

Technical features:

- Equipped with 3000 rpm rotor-stator homogenizer pump

- Separate gear motor system for scrapers

- Electrical panel with Japanese and Korean components

- Vacuum pump and vacuum level display

- Powder and liquid inlets with manual valve (upgradeable to pneumatic)

- Light and sight glass for visual control inside the tank

- Digital product temperature display for better process control

Customization options for laboratory vacuum homogenizer mixer

This device can be customized according to the specific needs of the laboratory or R&D unit. Some of the options that can be installed as a custom are:

- Variable speed system for homogenizer and spatula with speed display

- Triple-walled mixing tank for better thermal performance

- Independent hot water or hot oil package with temperature adjustment and circulation pump

- Possibility of installing a German IKA design batch homogenizer on the side tank

- Digital temperature indicator for side hoppers

- Installation of braked wheels for easy movement

- Operation with single-phase or three-phase electricity (according to customer order)

What factors does the price of a laboratory vacuum homogenizer mixer depend on?

The final price of a laboratory homogenizer mixer depends on several key factors:

- Tank capacity and production volume (usually 2 to 8 kg per batch)

- Added custom equipment (such as advanced pumps, braked wheels, heating or cooling systems)

- Type of electrical panel and brand of electrical components (Japanese or Korean brands cost differently)

- Body material and specific design desired

- Control system (mechanical, analog or digital)

- Vacuum or pressure capability

Important note: Buying this device is an investment in increasing production quality, reducing errors, and more precise control over the formulation. Therefore, spending more on customization will be logical and profitable.

Guide to Buying and Using a Laboratory Vacuum Homogenizer Mixer

To make a smart purchase and make the most of this device, consider the following points:

🔸Determine your daily or weekly production capacity. If you are in the research and development stage, an 8-liter capacity will be perfectly suitable.

🔸Is your final product sensitive to air or temperature? In this case, be sure to choose a model with a vacuum system and a heating/cooling wall.

🔸Select a control system that suits the operator. If you do not have skilled labor, use digital systems with a simple interface.

🔸Check the type of electricity in the workshop. If possible, three-phase electricity provides better and more stable performance.

🔸Ask the seller to provide the device with complete training, manuals, and after-sales service.

Also, after-sales service, technical support, and customization capabilities are features that should not be overlooked in the final purchase.

Price inquiry: +98 905 356 2923 +98 28 33857

Difference between a laboratory vacuum homogenizer mixer and a conventional mixer

Conventional mixers are mostly used for simple mixing of materials under normal conditions and do not have the ability to perform professional homogenization, temperature control or work under vacuum. However, the laboratory vacuum homogenizer mixer has significant advantages:

| Features | Conventional mixer | Laboratory Vacuum Homogenizer Mixer |

|---|---|---|

| Vacuum capability | No | Yes |

| Professional homogenizer system | No | Yes |

| Product temperature control | Limited | Advanced |

| Professional emulsion and suspension production | Limited | Advanced |

| Quality and accuracy of composition | Medium | Very high |

| Suitable for experimental formulation | Limited | Advanced |

Similar products: