VD series vacuum bubbler designed by Chroma Germany

Vacuum bubbler is a vacuum system for bubble removal of liquid, semi-liquid or paste products.

Applications

Food industry: All kinds of hot and cold sauces, pastry cream, cake gel, baby food, flavorings, food supplements, vitamins, juice

Cosmetic industry: Cosmetic powder, cosmetic pancake, lipstick, mascara, hair glue, mask, hair dye, varnish, creams, color pigments, lotions, toothpaste, shampoo

Pharmaceutical industry: Medical creams, gels and ointments, eye medicines and skin products

Chemical industry: Adhesives, ink and grease, varnish, microsilica gels in the construction industry, hard hydrocarbon homogenate, fertilizers, shoe polish, car wax, plant pesticides and agricultural pesticides

Bubbling at the highest standard

This device is used in quality assurance and production optimization in many sectors. In addition, it requires minimal supervision in its use and is also convenient and easy to clean in terms of maintenance. The machine offers different levels of automation and its interchangeable filter geometry allows it to be adapted to different products. The system is also fully CIP compatible.

Benefits at a glance

Prevention of oxidative effects such as discoloration and/or odor and taste changes, especially in the case of fats and oils

Consistently smooth, foamy and shiny surface for the product

Increased long-term stability (chemical stability and shelf life)

Optimum compatibility with the specific product

Increased dosing accuracy in downstream filling systems

Reduced packaging volume through increased specific gravity

Working principle

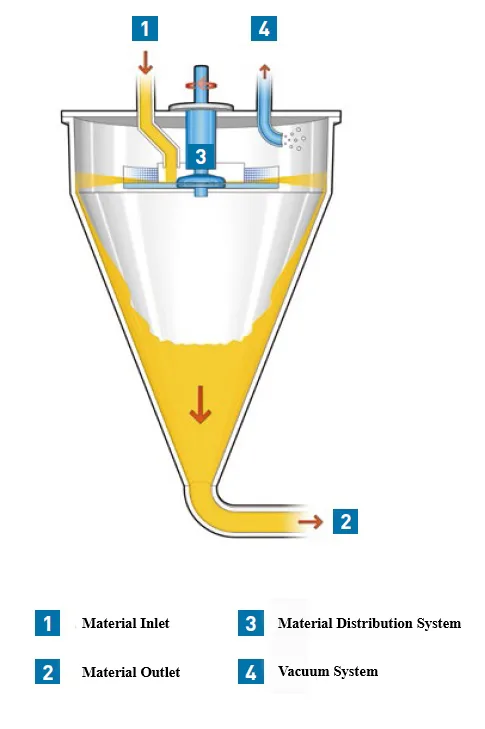

The product is spread as a thin layer on a rotating disc through a valve. Centrifugal force spins it through the filter cap onto the inner wall of the container, which is located underneath. Air or gas bubbles are released in this process and can be removed by a vacuum pump. A discharge pump transfers the product without bubbles to the next machine in the production line.

Standard design

Vacuum container with safety device

Thin film distributor with filter cap

Powerful vacuum system

Discharge pump

Simple operating control system

Options

Rising tube for foaming heavy products

Double-walled and insulated jacket

CIP cleaning system

Automatic level control

Lifting system for opening the container

Various filter caps

More options on request

In the production process of semi-thick liquids and high-viscosity products, bubbles of air (or other gases) are unintentionally formed in the product. This not only causes undesirable effects such as oxidation (spoiling of oil and fat inside the product), changes in aroma, taste, color and shortening of the product’s expiration date, but also creates numerous problems in weight packaging (especially tube packaging) due to the low density of the product.

The vacuum bubble trap designed by Chroma Germany is an ideal solution for eliminating trapped bubbles in high viscosity products.

This device, like a very precise filter, separates all bubbles from the product and improves the quality and texture of semi-solid products (various creams, sauces, hair dyes, ointments, lotions, toothpaste, etc.).

According to Chroma Germany’s recommendation, the most suitable place to install this device is immediately after the mixer or just before the filling machine.

Equipped with a pneumatic door, sight glass, independent vacuum pump with automatic vacuum control mechanism and speed adjustment by inverter.