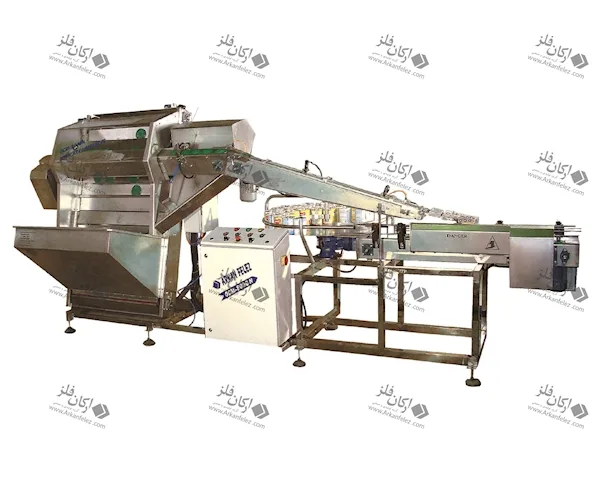

Applications

Cans of tomato paste, solid oil, baby milk powder, tuna, chips, coffee, etc.

General Product Specifications

- Contains a sorter set with the relevant motor and gearboxes.

- Ability to sort plastic doors with a minimum thickness of 3 mm (dry or soft material)

- Has a steel door transmission channel

- Has two electronic eyes on the door transmission channel (for automatic switching on and off the lift)

- Has a door assembly with a gearbox motor and related inverters

- Has a steel conveyor belt and steel chains

- Has the ability to adjust the diameter of the metal can

- Has the ability to adjust the height of the metal can

- Has the mechanism for placing the same distance between two cans in a row

- Has the ability to adjust the door speed by adjusting the input frequency to the electromotors

- Has the ability to adjust the pressure to place plastic doors on the metal can

- Maximum door speed of about 8000 cans per hour

- Has a traffic table to facilitate the entry of cans into the device from any direction

- Has an intelligent mechanism to stop the device in case of a drop in air pressure

Custom Options

- Has a mechanism for counting the number of output cans

- Has a mechanism for separating cans without plastic doors at the device output